Kemwell’s Approach to Considerations for Selecting Hydrolysates in Cell Culture Processes

Introduction:

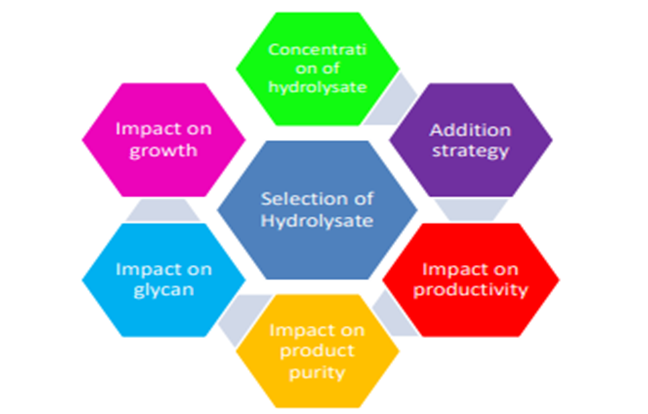

Hydrolysates have been used in cell culture media for cell growth and productivity enhancement. To finalize hydrolysate supplementation strategy, a comprehensive understanding of their impact on growth, productivity and product quality is required. This was achieved by performing structured experiments at small-scale to identify top performing hydrolysates.

Objective:

To improve CHO cell growth and titter productivity with addition of hydrolysates in medium or feed without impacting product quality.

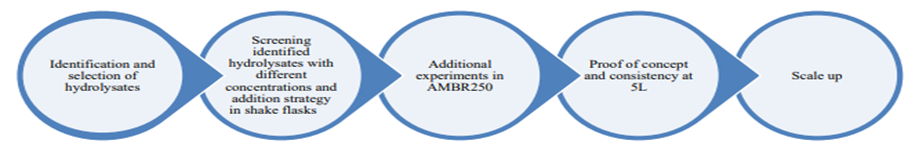

Approach:

Many studies emphasized the benefits of hydrolysates as additives in cell culture media on cell growth and productivity performances. However, to define hydrolysate supplementation strategies, a comprehensive understanding of their impact on cell growth and protein production is required. The effect of addition of two different hydrolysates SOY (SH) and COTTON (CH) during fed batch culturing was assessed on cell culture performances. Studies were conducted in shake flask and 5L bioreactors.

The study was started to understand the impact of addition of individual hydrolysate in medium. The SH at 10 g/L increased the cell density by 25 % and productivity by 12% whereas CH at 10 g/L inhibited the growth by 50% but due to increased specific productivity titer was same as SH. In the following study several conditions were screened with respect to different concentrations of SH and CH in chemically defined medium and also addition of hydrolysates in feed. Lower concentration of SH (5 g/L) yielded similar growth profiles and productivity as higher concentration (10 g/L) and also it was understood that addition of SH in feed has no impact. Addition of lower concentration CH (5 g/L) improved cell growth however specific productivity was reduced.

In CH conditions also, there is no advantage of addition of hydrolysate in feed. It was observed that in all the CH conditions higher product related impurities (HMW and fragments) were observed. In this study combinational effect of two hydrolysates was also assessed. But addition of both the hydrolysates in different concentrations did not improve productivity. Based on cell growth, productivity and product purity SOY hydrolysate at 5 g/L in medium was finalized.

Conclusion:

❖A comprehensive approach with step wise evaluation yields the best combination of hydrolysate with media or feed.

❖ Assessment of product quality and purity should be part of evaluation.

❖ Reproducibility of process is critical to finalize the process conditions.

To Know more please

Categories

New at Kemwell

A collection of stories about our people, our capabilities, our research,

and the ever-changing face of our firm.

Business Wire release Milestone expands India’s role in global biologics manufacturing;…

Introduction: Recent advances in biologics development are primarily focussed on development…

Introduction: Size variants determination is a critical quality attribute for a…